|

Clean everything up with a good supply

of compressed air, brake cleaner, and lint

free paper towels. This is essential;

Brawny won't do for this application. If in

doubt of the cleanliness before reassembling

a part, get out the brake cleaner. Buy 5

cans before you even start. While you're at

it, but a good set of safety glasses. First

time you ricochet this vulgar fluid into

your eyes, you'll see (nothing) why.

Use a file or some other abrasive tool

that you have good control over to remove

the staking on the nut of the stack. Don't

remove any more than you have to and don't

nick the seals, washers, or valve. After you

get the 12mm nut off, but before you remove

the anything else, remove a little material

from the circumference of the first two

threads. The staking distorts them and the

valve will not slide off over the bulge.

|

|

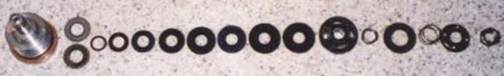

Now remove the washers and valve. Be

absolutely sure to keep everything

in order! Lay them out or hang them

on a piece of coat hanger, just

don't mix them unless you feel you

have a truly photographic memory.

Don't rely on the service manual or

fiche, they won't match

|

.

|

|

If a "plusher" ride is what you are

looking for, now you have to drill

the valve to mimic a "Gold Valve".

To the left is the valve with the

top two holes bored to; 3.64mm

/.0143 of an inch. Stock the holes

are 1.96mm / .0775 of an inch. That

is a huge difference!

|

|

Using a 9/64th of an inch (3.57mm) or

a #27 wire gauge bit (3.64mm)

you can drill the holes out.

Obviously this picture is just for comparison, you want to

drill all four holes.

Doing this mod will require that you run a

stiffer valve stack. Stock holes are

2.65mm on 2000~2004 models but, I

just did a 2005 that had 1.96mm

holes. The picture is of a 2003

compression valve with the top two

holes drilled out and the bottom two

left stock.

|

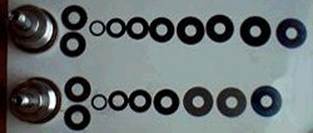

The picture to the top right shows

the stock (top) and modified

(bottom) compression stacks. This is

the standard "Fast Trail Rider"

setup. It's plusher, yet will still

handle 4' drop offs and some mild

jumping. To do this, starting from

the right, removed the 2nd, 3rd, and

4th (1-22mm x .10mm & 2-20mm x

.10mm) shims and replaced them with

two 21mm x .15 shims. All

fork shims have an ID of 8mm.

|

|

|

Reassemble the valve stack back onto

the core in the proper order, again

making sure that EVERY shim is

clean.

Install and torque the nut

to 25 to 30 INCH POUNDS,

this is very important.

More or less will change the way the

stack reacts to the oil pressure.

Stake the nut as shown

to hold it from coming apart. Only

use a threadlocker

(locktight),

if you make sure you get it only

on the threads on the nut or you

risk it wicking into the

valve stack and causing problems.

|

|

|

Single Track & Super Plush This is

the setup for everything from

Duel Sport, Desert to Single

track

Maxima 3wt light fluid

Stops bottoming about as good as stock

Compression valve drilled out.

|

Desert Racing, plusher then stock big rocks, big whoops, 4'+

drop offs, Racing

2.5wt or 3wt fluid

My Favorite

Compression valve drilled out.

|

Baja Racing, as plush as stock, Serious Racing

2.5wt or 3wt fluid

Compression valve drilled

out.

|

|

Rebound

|

Rebound

|

Rebound

|

|

(6) .10mm X 21mm

|

(6) .10mm X 21mm

|

(6) .10mm X 21mm

|

|

(1) .10mm X 13mm

|

(1) .10mm X

20mm *

|

(1) .10mm X 13mm

|

|

(2) .15mm X

21mm**

|

(1) .10mm X

13mm

|

(2) .15mm X 21mm **

|

|

(1) .10mm X

20mm

|

(1) .15mm X 21mm **

|

(1) .10mm X

21mm

|

|

(1) .10mm X 18mm

|

(1) .10mm X

20mm

|

(1) .10mm X 20mm

|

|

(1) .10mm X 16mm

|

(1) .10mm X 18mm

|

(1) .10mm X 18mm

|

|

(1) .10mm X 14mm

|

(1) .10mm X 16mm

|

(1) .10mm X 16mm

|

|

(1) .10mm X 12mm

|

(1) .10mm X 14mm

|

(1) .10mm X 14mm

|

|

(1) .10mm X 11mm

|

(1) .10mm X 12mm

|

(1) .10mm X 12mm

|

|

|

(1) .10mm X 11mm

|

(1) .10mm X 11mm

|

|

|

|

|

|

Compression

|

Compression

|

Compression

|

|

(2) .10mm X 22mm

|

(2) .10mm X 22mm

|

(2) .10mm X 22mm

|

|

(1) .10mm X 21mm

|

(1) .15mm X 21mm

|

(1) .15mm X 21mm

|

|

(2) .10mm X 20mm

|

(1) .10mm X 20mm

|

(2) .10mm X 20mm

|

|

(1) .10mm X 18mm

|

(1) .10mm X 18mm

|

(1) .10mm X 18mm

|

|

(1) .10mm X 16mm

|

(1) .10mm X 16mm

|

(1) .10mm X 16mm

|

|

(1) .10mm X 14mm

|

(1) .10mm X 14mm

|

(1) .10mm X 14mm

|

|

(1) .10mm X 11mm

|

(1) .10mm X 11mm

|

(1) .10mm X 11mm

|

|

(1) .40mm X

10mm***

|

(1) .40mm X

10mm***

|

(1) .40mm X

10mm***

|

|

|

|

|

* For smaller or less whoops in your

riding move this shim down with the

other .10mm X 20mm shim. this will be

better for single track and desert

racing.

** this is for .45kg/mm springs add

another .15mm X 21mm for .47kg/mm

springs

*** Don't have to have this.

|

Stock Bike (5wt oil)

|

Another

Shop (5wt Fluid) RB

|

Another

Shop (2.5wt fluid) PC

Nice for racing

|

|

Rebound

|

Rebound

|

Rebound

|

|

(7) .10mm X 21mm

|

(4) .10mm X

21mm

|

(5) .10mm X

21mm

|

|

(1) .10mm X 13mm

|

(1) .10mm X

16mm

|

(1) .10mm X

16mm

|

|

(1) .10mm X 20mm

|

(1) .10mm X

13mm

|

(3) .10mm X 21mm

|

|

(1) .10mm X 18mm

|

(3) .10mm X 21mm

|

(1) .10mm X

13mm

|

|

(1) .10mm X 16mm

|

(1) .10mm X 18mm

|

(1) .10mm X

20mm

|

|

(1) .10mm X 14mm

|

(1) .10mm X 16mm

|

(1) .10mm X 18mm

|

|

(1) .10mm X 12mm

|

(1) .10mm X 14mm

|

(1) .10mm X 16mm

|

|

(1) .10mm X 11mm

|

(1) .10mm X 12mm

|

(1) .10mm X 14mm

|

|

|

(1) .10mm X 11mm

|

(1) .10mm X 12mm

|

|

|

|

(1) .10mm X 11mm

|

|

|

|

Compression

|

|

Compression

|

Compression

|

(4) .10mm X 22mm

|

|

(2) .10mm X 22mm

|

(4) .10mm X 22mm

|

(1) .10mm X 16mm

|

|

(2) .10mm X 20mm

|

(1) .10mm X 14mm

|

(2) .10mm X

21mm

|

|

(1) .10mm X 18mm

|

(3) .10mm X 20mm

|

(2) .10mm X 20mm

|

|

(1) .10mm X 16mm

|

(1) .10mm X 18mm

|

(1) .10mm X 18mm

|

|

(1) .10mm X 14mm

|

(1) .10mm X 16mm

|

(1) .10mm X 16mm

|

|

(1) .10mm X 11mm

|

(1) .10mm X 14mm

|

(1) .10mm X 14mm

|

|

|

(1) .10mm X 11mm

|

(1) .10mm X 11mm

|

I get my shims from here: Race

Tech

Compression adjustment

should be close at 16 clicks out

and rebound at 11~12 clicks out.

Desert Race setup is a great all

around setup. With compression

valve drilled out and the lighter

fluid this is one plush setup that

resists bottoming a lot more then

the stock setup. I use 110mm of

fluid measurement* and less will

give a plusher ride to handle the

jagged rocks.

|

When working out

the rebound shim stack

you have to take into

effect how stiff the

spring you are using.

Stiffer springs

(.47kg/mm and higher)

need a stiffer slow

rebound stack.

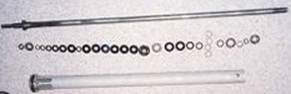

The rebound stack is located at

the end of the damper rod

that was attached to the

fork cap. With the

compression stack removed,

just pull up the rod. The

rod will come out with a

large aluminum piece (fork

damper) and a smaller piece

on the end, slightly cone

shaped, called the Oil lock.

|

|

|

Once the assembly is out, slide the

damper rod back down through

the damper to expose the

rebound stack. There is a Teflon

bushing in the damper end,

be careful not to score it

with the threaded rod end.

|

|

|

On the rebound stack I would run (6) 21mm

X .10mm, 13mm cross over shim, (2)

21mm X .15mm, (2) 20mm X .10mm, 18mm

X .10mm, 16mm X .10mm, 14mm X .10mm,

(I like leaving out the 12mm X .10mm

shim here, I use it elsewere.)

11mm X .10mm

Install and torque the nut

to 25 to 30 INCH POUNDS,

this is very important.

This valve setup, in combination with

.45kg Eibach

springs, will carry a 190lb rider

with gear with true finesse.

"It's as much an art as it is a

science"........ The stock setup has

to much

flow going through the by-pass

adjustment for full bend of the

shims to be reached. There is also a

mid-compression stack there also

that is just right if the adjustment

screws are a little stiff. You get

better control of rebound if more of

the fluid is forced through the

valve. With the lighter fluid you

can push more fluid at a faster

rate....closing down the by-pass let's

the shims control the flow more instead

of it just going through the by-pass

hole.

That's why I run at 11~12

clicks out on the rebound for the

forks. The

top adjuster on the Forks is to

adjust the rebound. I start this

at 11~12 click out (click the

adjuster in, clockwise, till it

just stops; then count 11 clicks

out). The Compression adjuster is

in the bottom of the fork under a

rubber plug. I start this adjuster

at 16 clicks out. Lots of trail

riders might want 18 clicks out

but, few need 14. These are good

starting points but, every bike

and rider is different.

|

I fill the forks with 650cc of Golden Spectro

Ultra light

(2.5wt) or Maxima 3wt suspension Fluid.

Then add till Measured to be 105~110 mm

from the top of the fork.

|

That's it, you're done with the

compression stack! If you are a fly

weight you can run stock springs,

then you can button things up and

call it a day. If you are in the

190lb or higher range and need to

run Eibach

.45 or heavier springs. You

will need to add a shim in the

rebound for stiffer springs. One

more 21mm X .15mm for each step up

in spring stiffness is close.

Cutting Stock Springs To Make them

Stiffer! Click Here->Stiffer

Springs

Cutting your 502~506mm (they settle) Stock

fork springs to 450mm and adding a

55mm long spacer will give you in

the range of .45kg~.46kg springs.

You will be surprised to find out that a

lot of High $$$$ fork springs that

are just one or two steps stiffer

are just that and come with the

spacer!

I buy my springs at Lindemann

Engineering: (909)

838-4587

79405 Hwy

111 Ste 9-270 La Quinta, CA

92253

They are fast and Honest about having

the spring or not! I have found Some

of the others are not or they rely on

what the computer tells them and they

don't have it.....then starts the

three month wait!

I DO NOT agree with how stiff of

springs Lindemann

Engineering recommends! Or how

stiff Race Tech Recommends! It seems

they use a computer program that is

setup for the MX track and/or

bikes. XR's Only and the others

are right on the money.

|

FORK &

SHOCK SPRING RATE GRAPH /

APPLICATION & RIDER

WEIGHT

|

|

|

Bike

|

Stock

Spring

Rates

|

140 lbs

|

160 lbs

|

180 lbs

|

200 lbs

|

220 lbs

|

240 lbs

|

260 lbs

|

280 lbs

|

300 lbs

|

|

XR400

120mm/

85mm

|

.382

kg/

9.9kg

|

.39kg/

8.6kg

|

.409kg/

9.0kg

|

.43kg/

9.5kg

|

.44kg/

10.0kg

|

.46kg/

1.05kg

|

.475kg/

10.6kg

|

.492kg/

11.0kg

|

.47kg/

11.4kg

|

.47kg/

12.kg

|

|

XR600R

125mm/

85mm

|

.39kg/

9.8kg

|

.392kg/

9.4kg

|

.409kg/

9.8kg

|

.426kg/

10.2kg

|

.442kg/

10.6kg

|

.459kg/

11.0kg

|

.475kg/

11.4kg

|

.492kg/

11.8kg

|

.47kg/

12.0kg

|

.47kg/

12.5

|

|

XR650L

130mm/

85mm

|

11.0kg/

92-3.41k

95001.44

|

.392kg/

10.3kg

|

.409kg/

10.7kg

|

.426kg/

11.1kg

|

.442kg/

11.5kg

|

.459kg/

11.9kg

|

.475kg/

12.3kg

|

.492kg/

12.7kg

|

|

|

|

XR650R

130mm

85mm

|

.43kg/

9.2kg

|

|

.41kg/

9.2kg

|

.43kg/

9.5kg

|

.45kg/

10.0kg

|

.45kg/

10.5kg

|

.47kg/

11.0kg

|

.47kg/

11.5kg

|

.49kg/

12.0kg

|

.49kg/

12.5kg

|

|

|

HOME HOME

|